The Sturdy Sewing Machine A Reliable Companion for Every Seamstress

Despite the numerous benefits, adopting auto cutter sewing machines comes with its own set of challenges. The initial cost of these machines can be high, which may deter smaller manufacturers. Additionally, training staff to operate sophisticated machinery requires time and resources, which can affect short-term productivity.

The Versatility of Chain Stitch Sewing Machines

- Lastly, a sewing machine for thick canvas should have a variety of stitch options to choose from. While straight stitches are commonly used when sewing canvas, having the ability to use other stitch styles like zigzag or decorative stitches can add versatility to your projects. Look for a machine that offers a range of stitch options and adjustable stitch length and width settings for maximum customization.

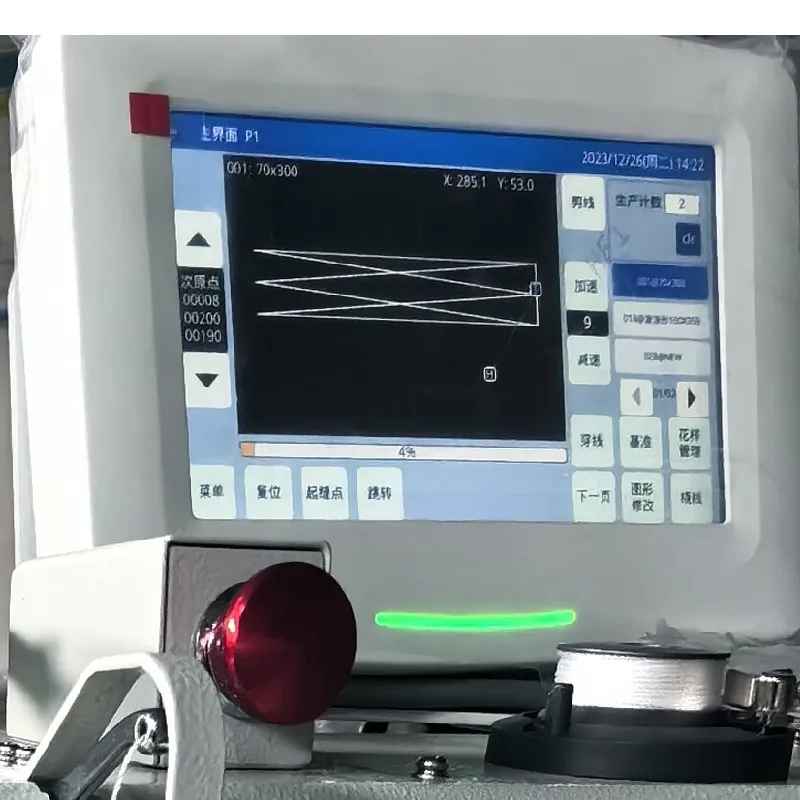

Sewing machines are classified into different categories: electric, computerized, mechanical, overlock, and embroidery sewing machines. These machines have basic settings and ought to be used manually. Electronic sewing machines have motorized functions. The computerized machines can even be connected to the internet.

Where Do I Find Replacement Needles For My Heavy Duty Sewing Machine?

Before you start sewing, it’s crucial to understand the type of leather you’ll be working with. Leather can vary significantly in thickness, texture, and strength. Common types include

The Versatility of Zig Zag Embroidery Machines

Many popular brands offer double needle walking foot sewing machines, each with its unique features and price points. For instance, brands like Juki, Singer, and Brother are well-known for their reliable and high-performing machines. Researching user reviews and expert recommendations can also help you make a more informed decision.

Features of a Zigzag Presser Foot

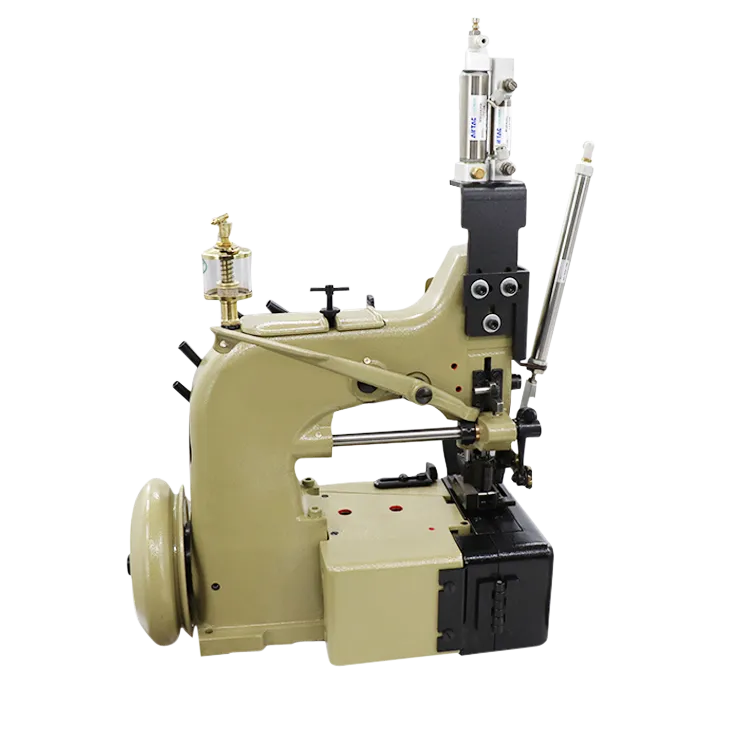

- Another advantage of a cylinder arm sewing machine is its speed and efficiency. The machine is designed to sew at a faster pace than a standard sewing machine, making it a valuable tool for high-volume production. Its ability to handle a wide range of materials and sewing tasks makes it a versatile machine for a variety of industries.

2. Preparing the Leather

7. Brand and Model Recommendations

Conclusion

The origins of CNC technology can be traced back to the 1940s and 1950s, when engineers began experimenting with automated machine tools. However, it wasn't until the 1980s and 1990s that CNC technology made its way into the sewing industry. The initial machines were bulky and limited in functionality, but as technology progressed, they became more compact and versatile.

This flexibility allows manufacturers to quickly adapt to changing market demands and produce a diverse range of products without the need for costly retooling This flexibility allows manufacturers to quickly adapt to changing market demands and produce a diverse range of products without the need for costly retooling

This flexibility allows manufacturers to quickly adapt to changing market demands and produce a diverse range of products without the need for costly retooling This flexibility allows manufacturers to quickly adapt to changing market demands and produce a diverse range of products without the need for costly retooling